What do you mean, Bean-to-Bar?

The Bean-to-Bar movement emerged in the early 2000s with more and more chocolate makers differentiating themselves from mass-produced chocolate.

Bean-to-Bar refers to a trade model where the chocolate maker controls every stage, from the purchase of the BEANS to the creation of the BAR. It also aims to shorten as much as possible the supply chain, and this is the key to ensure a trustful source of high quality beans and proper earnings for the farmers and workers involved in the harvesting and post-harvesting processes. Bean-to-Bar isn’t a protected label, but this is what it means (for us):

1. Traceability of ingredients and processes

We (and probably you too) want to know where our food comes from. The same counts for chocolate. Bean-to-Bar chocolate is typically more transparent about the full production chain, from the cacao bean to the chocolate bar. Let’s elaborate a bit on this:

Sourcing

This is the first and probably the most important step when it comes to the ethical chocolate making process. Cacao beans can be sourced from cooperatives operating in the countries of origin or through supply chain partners (distributors). Either way, they guarantee direct and fair trade with farmers who plant the seeds, grow the cacao trees and take care of the harvest and post-harvesting processes (i.e. fermentation and drying).

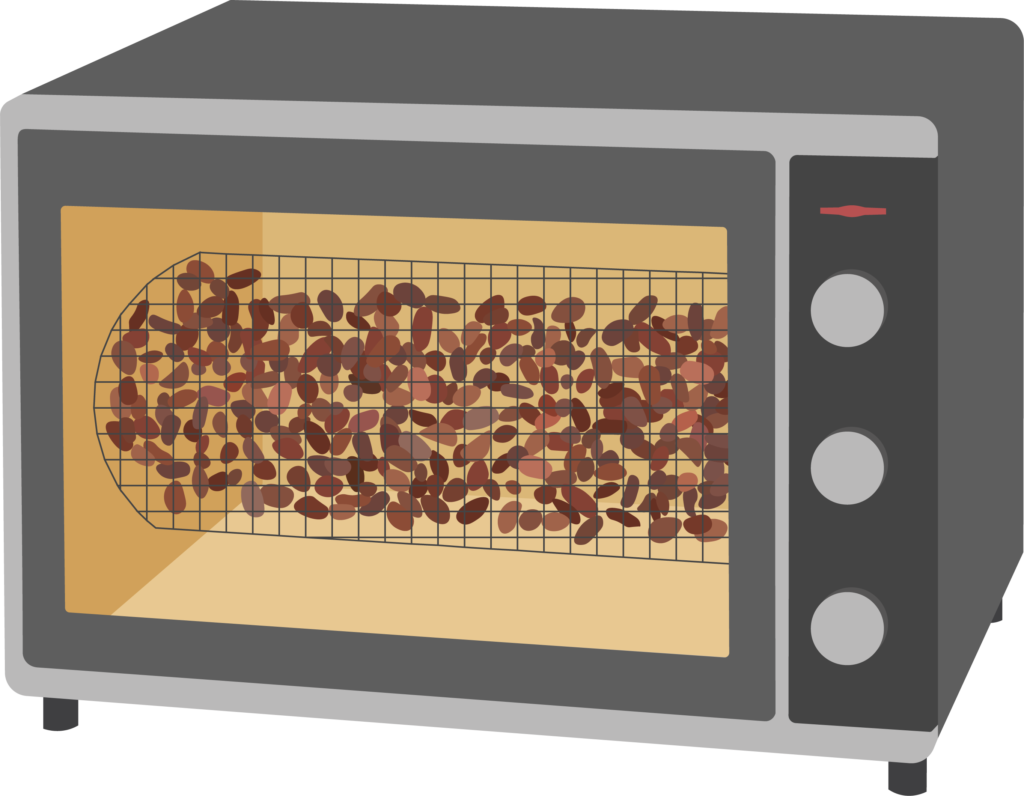

Roasting

Once the chocolate maker gets their hands on some nice (and ethically sourced) cacao beans that have been previously fermented and dried in the country of origin, the next step is to roast them. Roasting helps separate the outer shell (aka ‘husk’) from the inner bean and makes cracking and winnowing (the next step) much easier. It also sterilises the beans, reducing the risk of infections due to the presence of bacteria, fungi or mould. A famous bacteria is Salmonella. We definitely do NOT want that in our chocolate.

Roasting is a key process that brings out the unique flavours of cacao. The vinegar smell (acetic acid) from the fermentation process is ‘kicked out’ through evaporation. Raw beans don’t taste like chocolate. Roasted beans do.

IN GENERAL, the beans are roasted at temperatures somewhere between 110°C and 140°C during a time of about 20 to 45 minutes. The time and temperature of the process depends on the variety and also on what flavours the chocolate maker aims to bring out of the cacao beans.

Cracking and Winnowing

After the beans have been roasted, they go into a machine that cracks them into pieces of cacao nibs and husks (shells), to then separate them in a process called winnowing. Gravity and air are essential to this process. The husk is a fibrous material, flat and light. In contrast, the cacao bean has a higher density and a spherical shape, so the airflow allows the husk to rise and the heavier cacao bean is displaced for further processing.

Grinding

This is where the magic happens. In short, the cacao nibs are converted into smooth chocolate by impact and crushing effects of the grinding machine. The nibs are placed in a spinning drum with rotating roller stones, where they are ground to a fine texture. As the cacao butter is released from the inside of the nibs, we get a paste called cacao mass (or cacao liquor). At this point, sugar or any other ingredient is added. It’s up to the chocolate maker to add extra cacao butter to improve the fluidity and enhance the texture of the mixture.

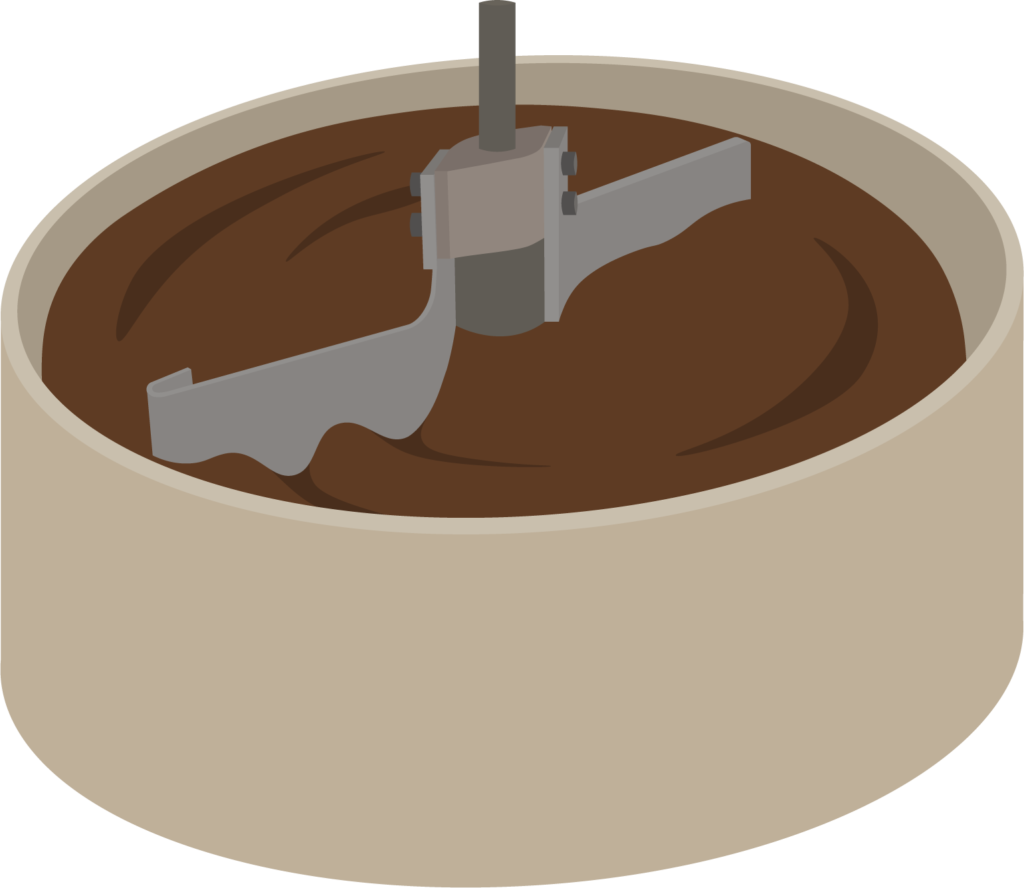

Conching

This is the process of refining the mixture of chocolate (cacao mass + sugar). This step is not strictly necessary. Again, it all depends on the preference of the chocolate maker.

It is a process considered to improve and harmonise the flavour of the chocolate and considerably optimises its fluidity, which will result in extremely soft and smooth products. Some chocolates have a ‘silky’ texture and this is thanks to this process. There is also a reduction of moisture in the mixture. This stage of the process must be long enough to homogenise the chocolate and eliminate undesirable aromas. However, by taking this process too long, you may risk losing some of the complex chocolate aromas that are desirable and important for flavour.

Tempering

Until now everything has gone relatively smoothly in the chocolate making process, but here is where things can turn out differently than expected. Tempering is certainly not the easiest step and it can represent a big challenge in order to get the perfect chocolate bar.

Tempering is basically a heat treatment that undergoes liquid chocolate. First, it is heated up to a certain temperature and then cooled down. The idea is to get the cacao butter molecules to crystallise evenly, resulting in a chocolate that is shiny, snaps nicely, has the correct hardness and is easy to remove from the moulds. Tempering can be done in a tempering machine or by hand.

Moulding

This is the method to give the desired shape to chocolate. After being properly tempered, the liquid chocolate is put into a mould. The moulds are manufactured with high-impact plastic materials such as polycarbonate. By vibration, air bubbles are removed from the chocolate. Once the chocolate is solidified (at a cool temperature), the bars can be ‘popped out’ of the moulds.

Packaging

This last step ensures the life of the product. Usually, Bean-to-Bar chocolates have some pretty cool packaging, not only when it comes to design but also to the materials they use. As we are all shifting towards more sustainable practices, the chocolate world cannot be an exemption. Artisanal chocolate makers are starting to use recycled and eco-friendly materials. In addition, the packaging must be attractive to the consumer AND informative at the same time. It indicates the ingredients present in the product, nutritional values and any other information that they want to share with their consumers, for example, information about the cacao beans, their origin and the people behind its making process.

2. (More than) fair trade

The chocolate industry has a long history of exploitation. Bean suppliers need to work towards direct-trade partnerships that benefit the cacao producer. It is important to source high quality beans and at the same time establish good relationships with farmers.

Farmer prosperity is a key ingredient in high quality beans.

We can say that farmer prosperity is intimately linked to the prosperity of the beans, the environment and the consumers. A farmer who gets paid fairly, is able to produce in a sustainable and organic way. They are also able to receive proper capacitation and to get the necessary tools or equipment to do their job. A proper reward certainly translates into a better outcome.

High quality beans + a bold chocolate maker = extraordinary chocolate!

We, as retailers (who are at the end of the supply chain), have the job to educate consumers about the difference between a product that is sourced fairly, with full transparency and a product that has no traceability and is cheap. If the chocolate maker is getting cheap cacao, it means that somebody in the supply chain is not making it, and most likely that is going to be the farmer.

We also want to become part of a network that rewards farmers who implement ecologically conscious and organic farming practices. A network that also supports and empowers women who are taking the lead in growing and harvesting cacao around the world.

Choosing socially and environmentally responsible food is the way to go. We want to spread awareness and encourage you to choose wisely…

3. Small batches and traditional methods

When we first tried Bean-to-Bar chocolate (not knowing it was Bean-to-Bar chocolate) we were so amazed by the high quality of it. By focussing on fine flavours and texture, the chocolate-makers enrich the sensory experience (similar to fine coffee or wine). They can only achieve this by buying small quantities of cacao. They clean, roast and grind the cacao beans themselves. Making chocolate this way certainly takes more time, more labour and it also costs more, but we can assure you that on each bite you take, you will taste the value of it.

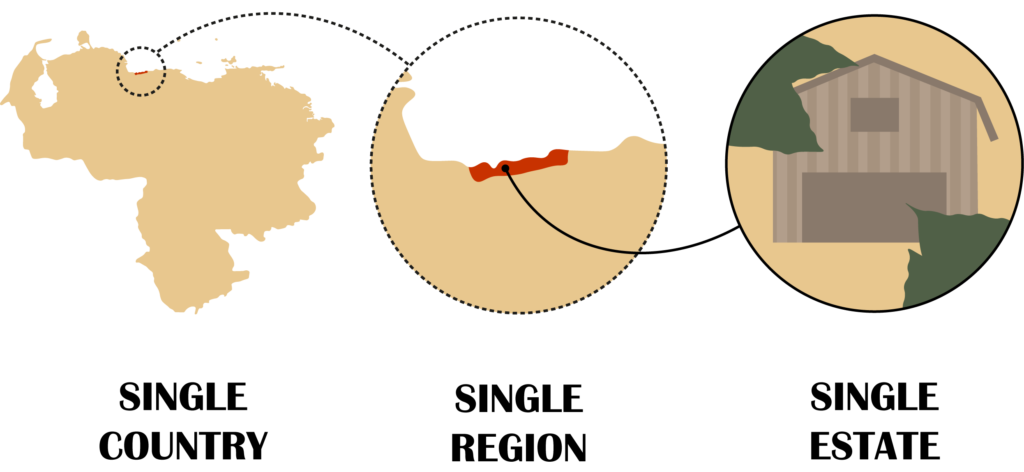

4. Single origin, natural flavours and nutritional value of cacao

All industrial or – as we like to call it – ‘supermarket’ chocolate tastes pretty much the same. We are talking about pure chocolate bars without any inclusions or flavouring. Big chocolate brands make sure their chocolate is constant in flavour. The newest batch must resemble the previous one. By using large quantities of low quality cacao beans and processing them quite aggressively, they eliminate unwanted flavours from their cheap cacao and ensure every piece tastes the same. Some of the tricks they use are; roasting at very high temperatures, adding stabilisers, emulsifiers, vanilla extract and, of course, tons of white sugar. We also have to recognise that not all ‘supermarket’ chocolate tastes bad. It is just very simple in taste (let’s say, boring!).

On the other hand, Bean-to-Bar chocolate will give you a unique experience with every bar you taste. Bean-to-Bar chocolate makers control the source of the ingredients they use. They don’t buy tons of ‘bulk’ cacao. They work instead with single origin beans (from a single region or even single estate). These cacao beans have unique flavours that are intrinsic to their strain, but they are also heavily influenced by the soil, climate and surrounding vegetation of the place where they are cultivated. It is then the task of the chocolate maker to bring them up to life. Every batch has a different roasting protocol, there is no need to add chemicals and they only use a limited amount of raw cane sugar or any other natural sweetener such as date sugar, coconut blossom sugar or even the (sweet) mucilage that covers the cacao beans inside the pod.

By making chocolate in an artisanal way, the nutritional properties of cacao are also preserved. You can read our health post to learn cool stuff about this topic.